TRIPLAN makes refineries around the world cleaner

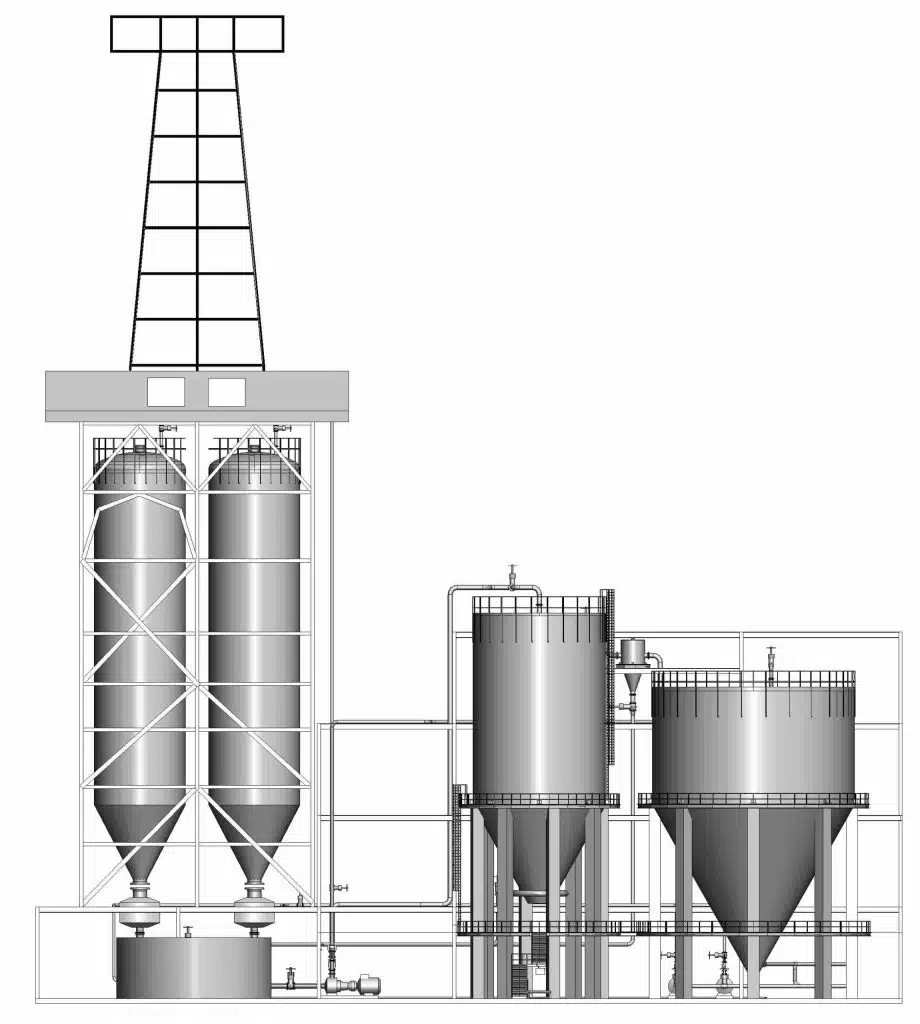

The Polish Grupa LOTOS commissioned the new delayed coker complex of the refinery in Gdańsk, Poland at the end of 2019, thus reaching a significant milestone in the EFRA project. The heart of the complex is the delayed coking unit in which the CCSS (Closed Coke Slurry System) process developed and patented by TRIPLAN has been integrated.

Thanks to the closed, space-saving CCSS system, which enables almost emission-free unloading, further processing and transport of coke, the environmental influences of conventional processes, such as the particle and pollutant emissions from open pit/pad systems, are avoided. Further advantages are the efficient dewatering of the coke and resource-saving water management, which is characterized by lower water consumption and effective treatment. In addition, the CCSS does not incur any higher investment costs and the ongoing operating costs are reduced thanks to the high degree of automation.

By building the DCU in the refinery complex, the operator can avoid the heavy work involved in crude oil processing Process residues into high-quality diesel oil, aviation fuel and petroleum coke, thereby not only protecting the environment but also increasing refinery margins. This is also important in view of the IMO2020 regulation of the International Maritime Organization (IMO), which prohibits the use of high-sulphur heavy fuel oil at sea from January 2020. With the successful integration of the CCSS into the DCU, this process will be further improved and thus represents an attractive alternative and a new state of the art to conventional coke handling in the open pit pad.

TRIPLAN was not only involved in the project as the licensor of the CCSS technology, but was also responsible for the CCSS system as an engineering partner and supplier of the key components.

TRIPLAN once again demonstrated its engineering and general planning skills ( EPCm) for complex refinery, chemical & Petrochemical industry proof.

“Grupa LOTOS with its refinery in Gdańsk is an extremely important reference for the still young CCSS technology,” emphasizes Peter Stromberger, Country Head Germany of the TTP Group. Ralf Gast, Managing Director of TRIPLAN GmbH, which is responsible for the project, adds: “The interest of international operators in CCSS technology has increased by leaps and bounds. For example, emission-free coke handling is an important argument for refineries in and near densely populated areas.”

The numerous advantages of the CCSS process were presented at the RefComm trade fair in Rotterdam at the end of 2019 presented to a wide international audience. In the meantime, several customers have become enthusiastic about the outstanding “green” TRIPLAN CCSS refinery technology. Many other refineries worldwide will follow and make the global refinery process cleaner and more environmentally friendly in the long term.